High Temperature Vulcanization

Introduction

High temperature vulcanization method for molybdenum disulfide is that in a high temperature environment and reducing gas, restore the molybdenum(vi)of Mo source (MoO3, MoCl3 etc.) to molybdenum(iv) and under vulcanization of sulfur source (H2S, gaseous S elemental) to prepare nano MoS2.

Molybdenum source is MoO3, when sulfur source is H2S, mechanism of reaction of sulfide are as follows: under high-temperature environment with the protection of the reducing gas, the molybdenum(VI) (MoO3, MoCl3, etc.) is reduced to molybdenum(IV), after vulcanization by sulphide (H2S, gaseous elemental S), nano MoS2 can be produced, whis process is called high temperature vulcanization. The advantage of this method is that the production of molybdenum disulfide nanostructures can keep in good condition.

Reaction Equations

Reaction equations (use MoO3 as molybdenum source) are as follows:

1)Protective gas is H2: MoO3 + 2H2S + H2 = MoS2 + 3H2O

2)Protective gas is inactive gas except H2: MoO3 + 2H2S = MoS2 + 3H2O + 1 / 8S8

3)At a sufficiently high temperature conditions, elemental sulfur vapor can restore MoO3 into MoS2: 2MoO3 + 7 / 8S8 = 2MoS2 + 3H2O + 3SO2

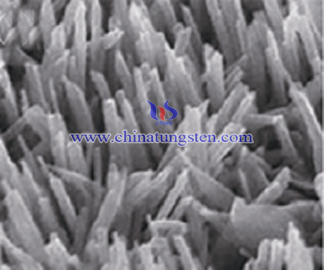

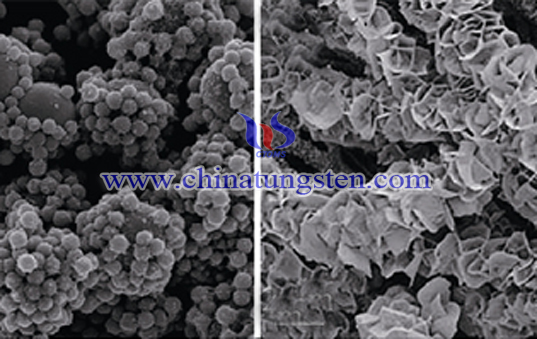

Crystalline of molybdenum disulfide made by high temperature vulcanization method can keep in very good condition, the probability lattice distortion is very low. And under different process parameters, MoS2 can be produced into different morphologies and structures. If heating MoO3 tube furnace to 850 ℃, and reduce itself, after high temperature gas-solid reactions MoS2 fullerenes nanoparticles and nanotubes can be produce. Under protection of reducing gas (Ar), reducing the molybdenum source at 550 ℃ for 20 min, and then put it in vertical arrangement at 220 ℃, length is about 10 nm. After the source of molybdenum (MoO3) was heated in air to 750 ℃ and held for 8 h, cooling it to room temperature to form a white or yellow fibrous samples, in vulcanization of elemental sulfur (350 ~ 1100 ℃, 4 ~ 10 h), hexagonal MoS2 micron chips can be made,which is relatively well-balanced growth.