Template

Introduction

As early as 1970, G.E.Possin, who produced a variety of wire whose diameter is only 40nm. In 1985, C.R.Martin and others, who used nano-porous polycarbonate membranes as templates to made Pt and Au nanowires series. The reaction space of template is in the nanometer size region, therefore, the size of the molybdenum disulfide would change because of different space.

Structure

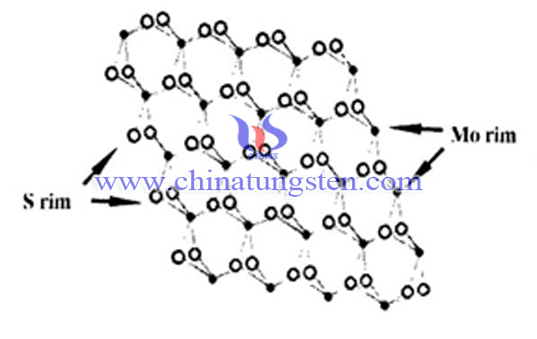

The layered structure of molybdenum disulfide is very similar with graphite, there is a Mo atom between the two S atoms layer, forming a three-layer structure. So there is a will there is a hanging edge of molybdenum atoms, leading to van der waals (VDW) between layers is weak, and it is vulnerable to be influenced by external environment.

Test Material

AAO template, dimethylsulfoxide, dimethylformamide, ammonium tetrathiomolybdate, and sodium hydroxide. The process is to take AAO template in N,N-Dimethylformamide precursor of dimethyl sulfoxide, after the liquid osmosising hole, remove it. Then put the template at 70 ℃ incubator to evaporate the solvent. Follow-up process is to pass gas, maintaining a high temperature, then molybdenum disulfide can be obtained.

Because this method requires a lot of additional preparation conditions, resulting in it cannot be widely promoted, and now it is used for laboratory to make molybdenum disulfide.