So far, rhenium is the most effective in improving the performance of elements molybdenum alloy.

Molybdenum rhenium alloy,because of its excellent performance, widely used in electronics, aerospace, nuclear energy and other high-tech fields. For example, molybdenum, rhenium alloy has excellent resistance to radiation, can be used for structural sheath materials for space heat ion exchanger reactor; molybdenum rhenium alloy has a high tensile strength and good ductility, and the foil can be made very filament material, a good elastic member; molybdenum rhenium alloy has good high temperature performance, can be used in a heater, a reflector, rocket propulsion, workstations, high-temperature devices such as a thermocouple, and has a long service life.

In addition, molybdenum rhenium alloy has good electrical conductivity, wear resistance and arc erosion resistance, the application of the electronic device is also very extensive. In short, with modern high-tech industrial development and needs, molybdenum rhenium alloy has very bright prospects.

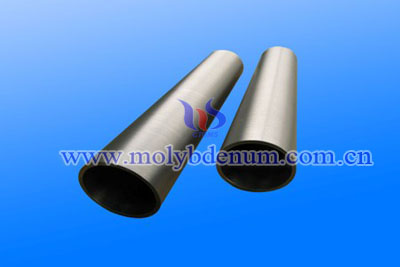

For molybdenum rhenium alloy production abroad as early as the sixties and seventies of the 20th century began to make a lot of research, especially in the U.S. Oak Ridge National Laboratory for the molybdenum rhenium alloys very system, while domestic molybdenum rhenium alloys for the start of the study later. However, the world can bulk supply manufacturers are few, it is even less domestic. U.S. Rhenium Alloys (RheniumAlloys, Inc.) Is one of the few manufacturers able to bulk supply, and now they produce molybdenum rhenium alloys, including molybdenum, rhenium alloy powder, wire, sheet, pipe and rods, its ingredients are Mo-41Re, Mo-44.5Re and Mo-47.5Re.

For domestic molybdenum rhenium alloy is not very system, preparation of molybdenum rhenium alloy technology is not very mature, especially for high-rhenium alloys are few studies on other elements molybdenum rhenium alloy content control is also problematic.

Due to the high rhenium molybdenum rhenium alloy super excellent performance, widely used in high-tech fields, and now the focus of study abroad is also here, especially Mo50Re (Mo-47.5Re), which in aerospace applications on particularly prominent. In addition, these alloys are used under high-temperature conditions are long, so molybdenum rhenium alloys for high temperature aging performance of research is also very necessary. For Mo-41Re and Mo-47.5Re prolonged aging process can be more profound analysis of the Re alloy segregation and phase structure of the change process, in order to determine the alloy performance changes during aging mechanism.

In addition, rhenium is very rare and expensive, to further explore the role of rhenium in molybdenum mechanism to seek alternative economic molybdenum rhenium alloy material is also very meaningful.

If you have any interest in our molybdenum rhenium alloy or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.