Molybdenum rhenium alloys are refractory alloys, it is generally by powder metallurgy method or prepared vacuum melting, both methods have advantages and disadvantages.

Prepared by vacuum melting molybdenum rhenium alloy ingots can be well controlled impurity content, especially gas element content decreased significantly, and the intermediate phase is not easily precipitate, which are conducive to the subsequent processing of molybdenum rhenium alloy. However, this method molybdenum rhenium alloy ingot prepared usually coarse grains, and uniform size distribution, which increases the difficulty of the alloy cogging.

Compared with vacuum melting method, molybdenum rhenium alloy prepared by powder metallurgy process is relatively simple, low cost, and relatively easier to achieve industrialization, therefore, almost all currently Gongshou products produced by powder metallurgy. But the law is not easy to control the powder metallurgy alloy ingot impurity content, generally sintered ingot and then by vacuum melting which can be well controlled impurity content.

The following will detail molybdenum rhenium alloy prepared by powder metallurgy process route.

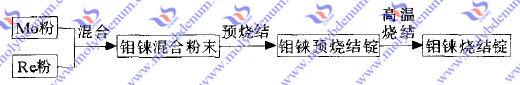

General powder metallurgy route shown in Fig.1. First, rhenium powder and molybdenum powder mixing, molding, or isostatic then, and after pre-sintering and sintering temperature greater than 2000 ℃ can be made of the relative density of 90% of the molybdenum rhenium alloy.

Preparation of molybdenum rhenium alloy powder metallurgy process route is as follows:

If you have any interest in our molybdenum rhenium alloy or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.