Molybdenum rhenium alloys are refractory alloys, it is generally by powder metallurgy method or prepared vacuum melting, both methods have advantages and disadvantages.

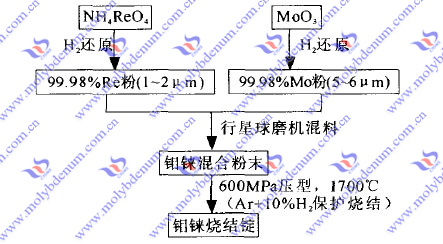

Grain and other studies have found that by controlling the reducing gas composition, gas flow rate reduction, reduction temperature and time parameters for MoO3 and NH4ReO4 to restore, you can obtain a fine powder and molybdenum rhenium powder, which rhenium powder particle size in 1 ~ 2μm, this mixed powder can be obtained through the medium temperature sintering sintering molybdenum rhenium alloy ingots, which process route as shown.

Medium Temperature Sintering Molybdenum Rhenium Alloys route is as follows:

The first difference is that the method is used in different raw materials, they use the material for the MoO3 and NH4ReO4, after mixing, the Co-reducing molybdenum rhenium alloy powder was prepared, the thus obtained mixed powder of small particle size, high purity, is conducive to the subsequent pressure type and sintering, and the sintering temperature dropped to 1700 ℃.

This process method, although the sintering temperature is reduced, but the density of the obtained sintered ingot generally reach 90% of the theoretical density, the alloy is some pores, which is currently prepared by powder metallurgy alloys are one of the problems.

If you have any interest in our molybdenum rhenium alloy or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.