Molybdenum and molybdenum alloy is used as a refractory metal, which combine good performance and low cost, has been widely used in the high temperature condition. Although sometimes also used vacuum arc melting or electron beam melting processes, but the most common is a molybdenum powder production methods. Particular by sintering or melting, and then extruding, rolling, forging, swaging or drawing and processed into semi-finished products. To overcome Molybdenum and molybdenum alloy high strength and ductility low heat caused difficulties, we have to take some special process.

Molybdenum and molybdenum alloys for high temperature applications are as follows:

Light bulbs

People use mixed with aluminum, potassium and silicon tungsten filament production and use of plastic good molybdenum wire will be fixed in the full light within. Sometimes, also used as a relatively hard molybdenum wire wound filament wick.

In the production of quartz glass bulb, encountered some special difficulties. Expansion coefficient of quartz glass is too small, it is difficult to achieve with any known metal material matched seals, on the contrary, a thickness of 0.025mm, the thin edge of a certain length as a pinch seal with molybdenum, and has been applied to the mercury-vapor lamp and quartz halogen .

Furnace

In order to meet the requirements of modern processing technology, metal, ceramic and composite materials to be in heat increasingly stringent conditions. Although a variety of metals and their alloys in large sintering process required to control the atmosphere, but it is widely accepted that in a vacuum or protective atmosphere annealing, hardening and brazing process has many advantages.

The furnace used in these processes of the internal structure of the material has some special requirements, including high temperature, but also has high purity and a low vapor pressure. Refractory metals (molybdenum, tungsten, buttons, Ni) is very suitable for high temperature furnace components, its main application areas are: first, by a wire, rod, strip, plate or mesh material produced by resistive heating element, and the second, the furnace wall protective heat shield parts, the third charge filling and stacking used boats, trays, slide rack and bracket; fourth, temperature monitoring and control and so on.

Push a special heat stove fireplace, usually under a reducing atmosphere or in the protection of sintered metal and ceramic powder. It has a ceramic heating zone of the hearth, and the rest are lined with refractory bricks. External furnace shell is a metal plate. Placed in the heating zone of molybdenum or molybdenum wire with a continuous heating element, and sometimes also with molybdenum heating element is fixed to the hook on the lid.

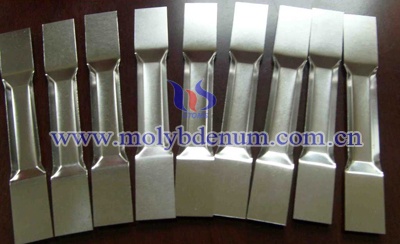

In the sintering furnace is used to pass the workpiece boat or trays, usually the use of pure molybdenum sheet folded, riveted or deep drawing formed. For some high temperature processes is to use TZM molybdenum alloy (Mo-0.5% Ti-0.08% Zr-0.025% C) as well, because of its hot strength and high recrystallization temperatures. Recognized uranium particulate titanium sintered nuclear fuel is a good example. As in the nuclear industry require materials at high temperature of about 1800 ℃ has excellent creep resistance, have been developed such as the new special aluminum rare earth-containing alloys.

Cold fireplace

The use of this type of furnace volume heat fireplace larger, faster heating and cooling, thus, include a program for batch heat treatment, heat and cooled is very desirable. Cold fireplace outer wall of the water-cooled vertical or horizontal cylindrical shell, a heat shield must be used to protect the metal plate, so that from heat radiation. In such a furnace, usually a wire or rod-shaped heating element, of course, are often used with the heating element or mesh. Heating element and the heat shield material is mainly based on the operating temperature of the furnace and design requirements to choose. From economic considerations should first select molybdenum, it is suitable for the temperature at 1825 ℃ under continuous operation.

If you have any interest in our molybdenum alloy or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.