Molybdenum Disulfide Nanoparticle Processes - Mechanochemistry

Introduction

Mechanochemical method is a solid phase synthesis technology, its essence is the use of mechanical energy to induce a chemical reaction and induce changes of the material organization, structure, and properties, it is widely used in the preparation of new materials and surface modification. In the process of grinding, physics - chemistry of solid mattercaused by the mechanical force is very prominent, in addition to lead to split, break, deformation and volume thinning and other physical changes (mechanical activation effect), it would have energy conversion, introduce chemical changes of the material, which create variety of crystal defects, dislocations, or fault.

In general, the catalytic activity of the solid catalyst is determined by active points, usually in the form of the presence of surface defects. Expose more metal sites can significantly improve the reais ctivity of metal-catalyzed reactions. Therefore, mechanical milling is widely used in the manufacture of crystal defects and dislocations, to improve the catalytic activity.

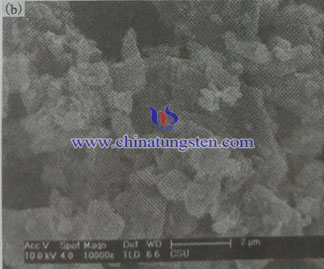

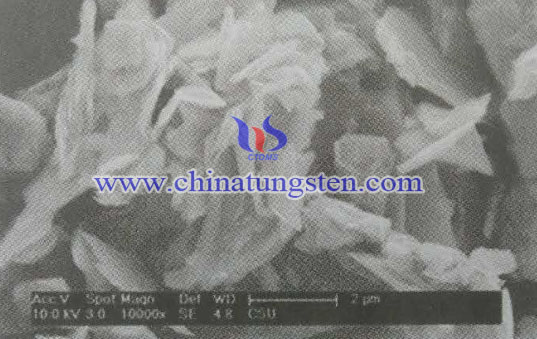

Mechanochemistry method is to use MoS3 as precursor by high energy ball milling, using its local effect instantaneous high temperature and pressure to prepare a molybdenum disulfide nanoparticles which have a large number of active sites. 3.4g (NH4) 2MoO4 and 10g Na2S are dissolved in deionized water, adding an appropriate amount of hydrochloric acid, MoS3 precursor precipitate can be obtained after fully stirred. Then prepare a molybdenum disulfide nanoparticles which have a large number of active sites by high energy ball milling.

Molybdenum disulfide nanoparticles made by mechanochemistry method can easily be represented by the following formula: MoS3 → MoS2 + S