Molybdenum Disulfide Nanoparticle Processes - Ultrasonic Irradiation

Introduction

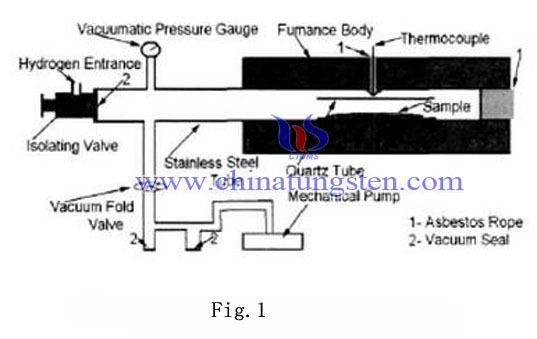

First, an appropriate amount of sulfur powder is dissolved in a mixed solution of CCl4 and CS2, until the S is completely dissolved, the solution is added MoO3 nanoparticles prepared by sonochemical (molar ratio of MoO3 and S 1: 3). After stirring for 15min, ultrasonic dispersion for 30min, at room temperature for natural ventilation evaporated to give uniformly coated surface S in MoO3 composite powder. The MoO3 / S composite powders are uniformly spread in a quartz tube and placed in a homemade vacuum furnace (Fig. 1), the reaction apparatus is evacuated to 1Pa, then slowly introduce into high purity H2 to 0.5 × 105 Pa. Then the furnace is heated to a set temperature (400,450,500,550,600,700℃), heating rate of 10℃ · min-1 and insulation for 1h, collecte gray and black powder samples.

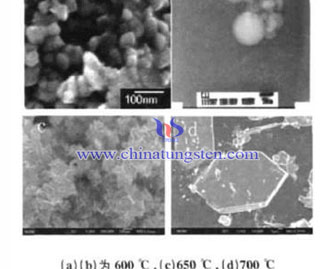

Figure 2 (b) TEM photo shows that at 600 ℃, the reaction time was 1h, molybdenum disulfide nanoparticles formed spherical particle diameter of about 70nm, FIG. 2 (a) TEM photo shows a large number of particles are spherical, maintaining the original shape of MoO3. Figure 2 (c) shows synthesized molybdenum disulfide nanoparticles is formed at 650℃, showing the sheet-like morphology. When the temperature reaches 700 ℃ as FIG, the crystalline form is more complete 2 (d), showing regular hexagonal structure, and the particle size is increased. It can be seen as the temperature increases the particles continue to grow, and crystalline is more complete. Therefore, the temperature control at 600℃ can obtain spherical nanoparticles.