Molybdenum Disulfide Nanosheet - Vulcanizing Temperature and Time

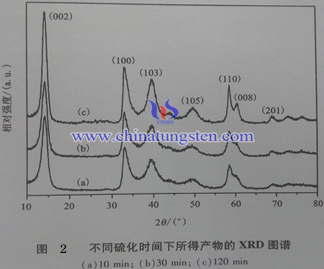

Vulcanizing Temperature

Figure 1 is XRD pattern of molybdenum disulfide nanosheets at different vulcanizing temperatures. At a vulcanization temperature of 400 ℃ ~ 700 ℃, pure product can be obtained, and when the temperature reached 800 ℃, because the sulfur volatile too fast, which would cause the incomplete of vulcanization product, leaving intermediate product molybdenum dioxide [FIG. 1 (e)]. When the vulcanizing temperature is 300 ℃, molybdenum trioxide did not react, after firing in two hours under an argon atmosphere, only detected molybdenum trioxide, sulfur of mixture has evaporated with the gas stream [Figure 1 (f)]. Meanwhile, with the rise of vulcanization temperature, the product began to appear more diffraction peaks, and they become sharply, indicating that the degree of crystalline is increasing.

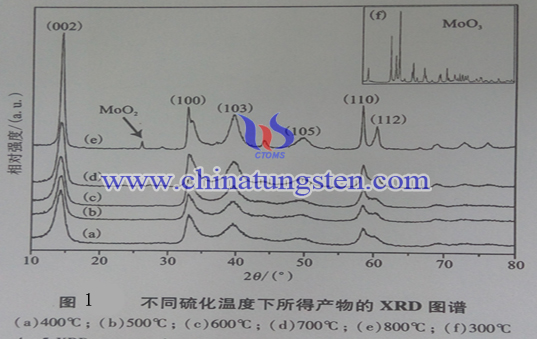

Vulcanizing Time

Figure 2 is a XRD pattern of the product at various times vulcanized of 600 ℃. Even just kept 10min at this temperature, you can still generate pure molybdenum disulfide [Figure 2 (a)], all of the diffraction peaks are compatible with standard hexagonal molybdenum disulfide. Strong diffraction peak of the extent of the crystalline product well. In the extended firing time, the intensity of all the diffraction peaks have a slight increase, indicating that the degree of crystallinity of the product is further improved. When the curing time 120min extended time, (105), (008) and (201) peaks become more apparent and acute.