Molybdenum Disulfide Nanosphere - Friction Performance

Introduction

Due to molybdenum disulfide nanoparticles unique rolling friction mechanism, the product is used as an important lubricant additive in various artifacts.

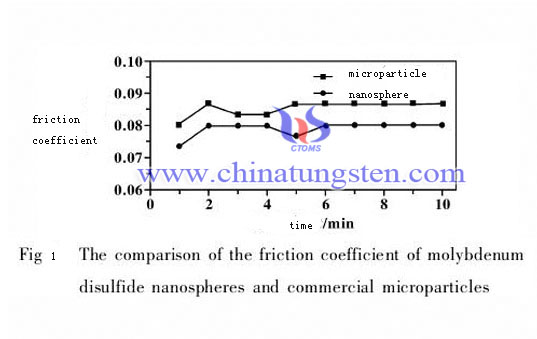

Compared the molybdenum disulfide nanospheres and commercially available ultrafine powder of molybdenum disulfide, it can be seen that the integrated frictional properties of molybdenum disulfide nanosphere is far superior to the latter. Because it has special nano-size effect and structural optimization mechanisms, having a small friction coefficient, high load capacity and excellent anti-wear reducing performance. As shown in Fig.1, under the same experimental conditions, molybdenum disulfide nanoparticles friction factor is less than commercially available ultra-fine powder of molybdenum disulfide, and gradually stabilized with the extension of friction time.

On the one hand, because nanoscale particles is relatively small, and it has high surface activity energy, easily and firmly to be adsorbed on the substrate surface, thereby enhancing the resistance load, and it can fill the pits of the substrate surface to form a dense lubricating protective film, so that the friction quickly reach stable. In addition, at the beginning of friction, "rolling friction" approach can effectively reduce wear and tear caused by the friction. Lasted for some time, spherical structures would be broken because of the friction, thereby becoming smaller nanometer particles of debris.