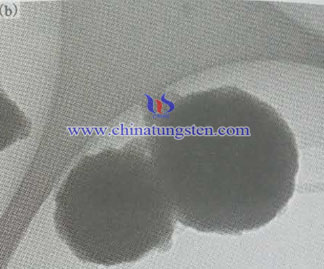

Molybdenum Disulfide Solid Nanosphere

Manufacturing Process

0.85g (NH2) 2Mo2O7 and 3.06gNa2S · 9H2O are dissolved in 100mL deionized water, as a solution of the A. Meanwhile, 2.88g of polyethylene glycol (PEG-20000) is completely dissolved in 100mL deionized water as a solution B. Mix A and B solution, and add excess hydrochloric acid for continuous stirring, until the color of the solution will not change again. The precipitate is then filtered, respectively use ammonia, ethanol and deionized waterto wash it for several times until the pH is neutral, and then put it in the oven and dried at a temperature of 50 ℃ for 6 hours to obtain a precursor. Then the precursor reduct in tubular resistance furnace with the hydrogen under the conditions of 400 ~ 800℃ for half an hour to obtain the final product of molybdenum disulfide solid nanosphere.

Although there are a variety of methods can prepared a variety of different topography of molybdenum disulfide nano-materials, at present only the best globular structure can exhibit lubricating antifriction properties, spherical structure is based on rolling friction mechanism, which can effectively reduce friction and wear.

As an organic macromolecule, PEG has the fuction of coating effective for nanocrystalline by "steric effect" and promote to obtain a spherical structure. Because of its efficient "rolling mechanism", the special appearance of nanoparticles can effectively reduce friction and wear, which is a potential super lubricant.