Liquid Ultrasound

Introduction

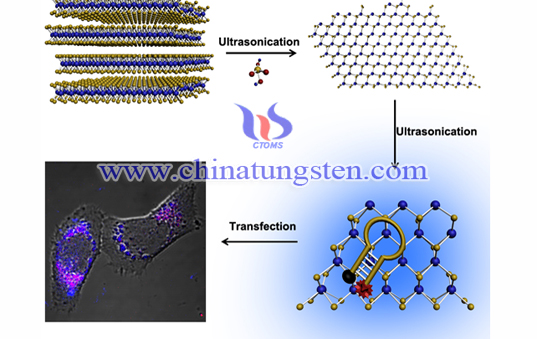

Ultrasonic liquid is a new way. Generally, second-rate landscaped powder was added directly in a particular organic solvent or water, using ultrasonic to prepare single or multiple layers of molybdenum disulfide solution.

In 2011, Coleman and others used different solvents for peeling MoS2 and other two-dimensional materials. The result showed that when the liquid peel nano-materials, if the surface of the solvent can be suitable for layered material, it can achieve the best peeling results. Two-dimensional surface of the material is relatively high, so the boiling point of the dispersion solution is relatively high. Solution of MoS2 ultrasonic peeling liquid mainly include NMP, dimethylformamide (DMF), N- cyclohexyl pyrrolidone (CHP).

In order to achieve better MoS2 nanosheets, many researchers turned single solvent into different mix solvent. Researchers mixed solution of water and ethanol to peel graphene inorganic material (IGAs) MoS2, tungsten disulfide (WS2) and boron nitride (BN). The results showed that the effect of the peel of water and ethanol mixed solvent is much better than a single solvent. By calculating Hansen solubility parameter, when the ethanol volume fraction of 45%, MoS2 concentration is maximum. There is another method which is to use a mixed solvent of chloroform and acetonitrile to peel and obtain MoS2 nanosheets. also confirmed the above conclusions. The method use two low-boiling solvent are mixed to disperse the IGAs has a low cost, low toxicity, large range of options and other advantages, which is good choice for dispersed nanomaterials.

Compared to the micro-mechanical peeling and Li ion intercalation, although efficiency of liquid ultrasonic method is relatively low, but it is simple and it can also be mass-produced.