Lithium Ion Intercalation

Introduction

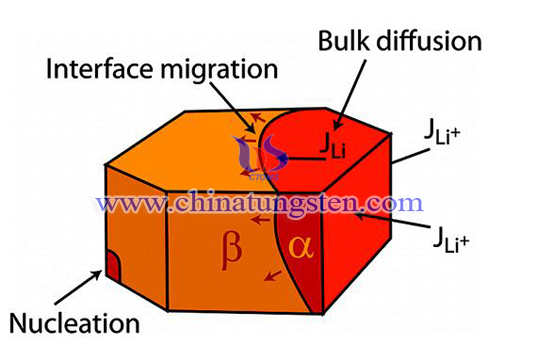

Lithium ion intercalation method is the use of intercalation agent, such as butyl lithium is inserted into the two-dimensional layered nanomaterials, increasing the interlayer spacing of material to weaken the van der Waals forces, and then ultrasound, and ultimately get a single layer nanosheet.

Bang and others used N- methyl-2-pyrrolidone as a solvent and an alkaline earth metal hydroxide as intercalant, then high concentration two-dimensional MoS2 nanosheets can be made by intercalation. During the processes of pelling by this method, the alkaline earth metal cations insert MoS2 layer can weaken the van der Waals forces, and then use ultrasound to further improve the peeling efficiency. Experiments show that the smaller radius of the cation, the higher the peeling efficiency.

Zeng and others used Li foil as an anode, MoS2 powder coating at copper as a cathode after drying in vacuo, ethylene carbonate and dimethyl carbonate is dissolved LiPF6 at the proportion of 1: 1 electrolyte, under an argon atmosphere inlet current to complete the embedding process. After energization intercalation, washing and ultrasonic peeling to obtain 1.0nm thickness MoS2 nanosheets with 92% monolayer MoS2.

Lithium ion intercalation has high peeling efficiency and wide application, but the process takes a long time, and it is easy to aggregation MoS2 when remove lithium ion.