Does different annealing temperature has any effect on TZM alloy organization ?

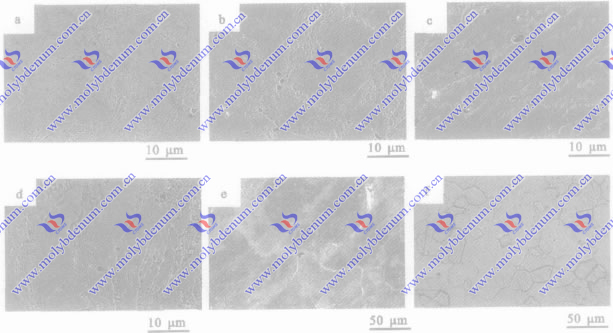

TZM alloy at different temperatures the microstructure after annealing are shown in Fig.1.

As can be seen from Fig.1, organized by the sample annealed at different temperatures. 850 ℃ sample microstructure memory of local grain boundaries and in many smaller inclusions, and distributed evenly, the performance of loose tissue. 950 ℃ sample in the presence of grain boundary inclusions larger size holes, about the size of 3μm, which is causing the temperature of the main reason for low elongation. 1 150 ℃ annealing phase diagram of the sample remains localized holes, but the size is small, relatively dense tissue, the extruded fibers expand and broadened, partial removal of internal stress, the performance improved tensile properties.

The recrystallization temperature of TZM alloy(titanium zirconium molybdenum) is approximately 1 200 ℃, from the selected temperature is below the recrystallization annealing temperature in several view, Fig.1a is a reply to the initial stage, low temperature, TZM alloy inclusions and other defects that exist within no longer large, showing the material is relatively dense, and as the temperature rises, various defects in the crystal grown, some of the mixed off, leaving large holes. The temperature rises, some of the compounds was dissolved again in the matrix. Inclusion on the tissue components were analyzed to obtain the impurity elements such as silicon and its oxides of carbon and titanium, zirconium carbide, it is these particles and particle inclusions enhancer makes the existence of high performance alloys have been very large increase, while making the plastic down.

Fig.1 TZM Alloy Aannealed Microstructure

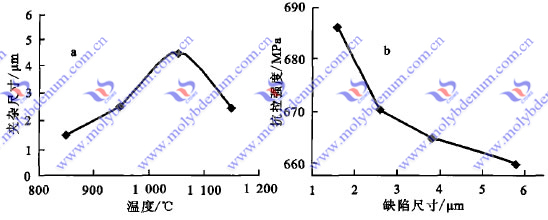

Fig.2 Inclusion Size and Temperature (a) and Intensity (b) of the Curve

In addition, the size of holes from the defect Relationship between the temperature (Fig. 2(a), at 850 ~ 1 050 ℃ range, as the temperature increases, the pore size becomes large organization, when the temperature reaches 1 150 ℃, the size becomes smaller, mainly due to the inclusions and other defects in low temperature in the substrate grow, pores exist in the performance of the microstructure, as the temperature rises further, the number of re-dissolved carbide matrix. From the inclusion size and tensile strength of the curve (Fig.2(b) shows that the inclusion size increases, the tensile strength decreases, which is the temperature on the tensile strength of the same.

If you have any interest in our TZM alloy(titanium zirconium molybdenum) or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.