TZM Alloy(Titanium Zirconium Molybdenum) Annealing Process As Follows:

TZM alloy by deformation strengthening, the general will have a residual stress. In order to eliminate residual stress, while changing the alloy brittle, generally have the alloy is annealed. Annealing, select the annealing temperature is essential. Annealing temperature can affect not only the hardness of the alloy, and the tensile properties of the alloy can also have a greater impact.

Reported in the literature prepared by vacuum arc melting molybdenum TZM alloy, by extrusion after annealing, when the annealing temperature from 950 ℃ up to 1050 ℃, alloy strength and elongation at room temperature is not changed, but the annealing temperature from 1 150 ℃ up to 1 600 ℃ when the elongation of alloy at room temperature was increased, the tensile strength decreased significantly.

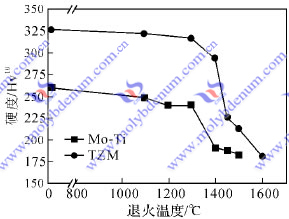

Fig. 1 annealing temperature on TZM alloy hardness of the alloy the impact of

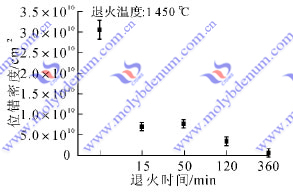

Fig.2 TZM alloy annealing time on the dislocation density of

Fig.1 shows the annealing temperature on the Mo-Ti alloy and a hardness of molybdenum alloy TZM diagram can be seen, as the annealing temperature, TZM allopy(Titanium Zirconium Molybdenum) reduce the hardness of the alloy, especially when the annealing temperature is 1400 ~ 1500 ℃, the hardness decreased is obvious, this time can be considered at this temperature grains grow significantly. Annealing temperature is too high, easy to grow grains occur while being able to quickly eliminate dislocations, lattice distortion and other defects, thereby enhancing the ductility of the alloy, tensile strength decreases.

Fig.2 is a molybdenum TZM alloy annealed at 1450 ℃ different time change of the dislocation density. Can be seen at 1450 ℃ TZM molybdenum alloys annealed for 15 min, the dislocation density is already from the initial 3 × 1010cm-2 decreased to 7 × 109cm-2, the higher the annealing temperature, short time can be drastically reduced so that the dislocation density.

Generally in a vacuum or hydrogen annealing under the protection, but recently researchers also use nitrogen annealing, the annealing of the alloy, while nitriding. TZM molybdenum alloy after nitriding, the base body to produce titanium nitride particles, so that the hardness and tensile strength has been further improved.

If you have any interest in our TZM alloy(Titanium Zirconium Molybdenum) or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.