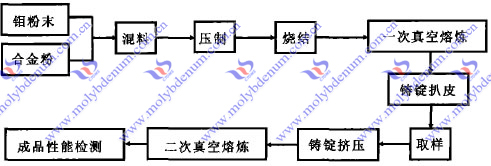

Vacuum arc melting method to obtain TZM alloy(Titanium Zirconium Molybdenum), specific preparation process is shown in Fig..

Molybdenum powder and alloying additives are mixed in the mixer after loading, then isostatic pressing machine made billets, will go through a sintered billet melting resistance welding electrodes, with the secondary vacuum consumable arc melting, ingot prepared, to be finished TZM alloy.

Fig. TZM alloy preparation process flow diagram

TZM alloy composition requires C, O, N impurity content of less than 6 × 10-5, of the material to the requirements of a low impurity content gas, using electron beam melting method to remove gaseous impurities. Vertical extrusion extruder at 600 t on, select 110 mm extruder barrel temperature 1 600 ℃, extrusion ratio of 2:1.

Table TZM alloy composition

| w(Cr) | w(Ti) | w(Zr) | w(O) | w(C) | w(N) |

| ≤3×10-4 | ≤0.4% | 0.05%~0.25% | 6×10-4 | <6×10-4< | 6×10-4 |

If you have any interest in our TZM alloy(Titanium Zirconium Molybdenum) or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.