Molybdenum alloy plate rolling process annealing temperature analysis as follows:

Molybdenum alloy plate rolling process, with the increase of the degree of deformation, rolling tough plastic elevated degree of toughness decreases. The lower the deformation temperature, the deformation increases, the stored energy within the rolling higher to further warm rolling, cold rolling and subsequent cold forming difficult. Before the formation of recrystallized grains, the annealing temperature for rolling back will occur. Low back when the movement of the point defect density greatly reduced; moderate and high temperatures reply, the movement of dislocations generated Polygon, with slip, climb progresses, the dislocation density decreases, microstructure appears Subgrains; continue to improve recrystallization temperature change occurs.

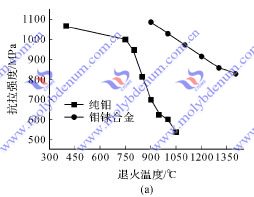

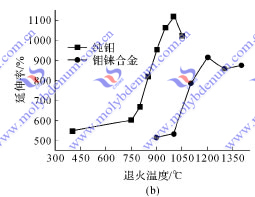

Pure molybdenum plate and molybdenum alloy plate lower than the recrystallization temperature, in order to prevent coarse grains, the annealing temperature is low. Rolling process, annealing treatment embodied in tensile strength with increasing temperature, micro-hardness decreased, elongation increased. The following figure is pure molybdenum plate and molybdenum rhenium alloys (3% Re) plate rolling process of annealing treatment on tensile strength and elongation diagram.

Pic. The Relationship Between Annealing Temperature and Tensile Strength and Elongation Diagram

As can be seen from the figure, pure molybdenum plate and molybdenum alloy plate tensile strength and elongation with annealing temperature has the same trend. Pic. represents the molybdenum and molybdenum alloy sheet after rolling annealing temperature on the mechanical properties of the relationship. In general, the response to tissue retention can significantly improve the tensile strength, elongation and other mechanical properties and facilitate the subsequent conduct of the rolling and deep processing. Rolling production should be based on the characteristics of different alloys annealing process to develop a reasonable

If you have any interest in our molybdenum alloy plate or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.