Molybdenum alloy single crystal process as follows:

In Table shows the nominal composition of raw materials, these materials are solid bar prepared by powder metallurgy. Vibration grinding machine in the powder mixing, in a stainless steel mold and then cold pressing, and then sintered in a vacuum furnace to suppress out of the green, the process conditions are: a vacuum of 10-8 Torr and a temperature of 1 873 K, time was 16 h.

According to the determination, the relative density of the blank annealing was 95%. Upsetting the billet into a desired length, and the single crystal material into a single crystal growth furnace. The crystal growth apparatus molybdenum alloy with a large-capacity cryopump furnace evacuated to a vacuum before the heating is maintained at the level of 10-8 Torr. In the crystal growth process, the exhaust gas is caused by the maximum pressure chamber 10-6 Torr.

Zone melting heat source is an electron beam bombardment. Because the material has a porosity of about 5%, so that the emission of the gas to bring a lot of problems. Order for the device in the smelting process can sufficiently eliminate raw materials into the gas along the scanning direction and lower solute segregation zone scanning speed has to be sufficiently low.

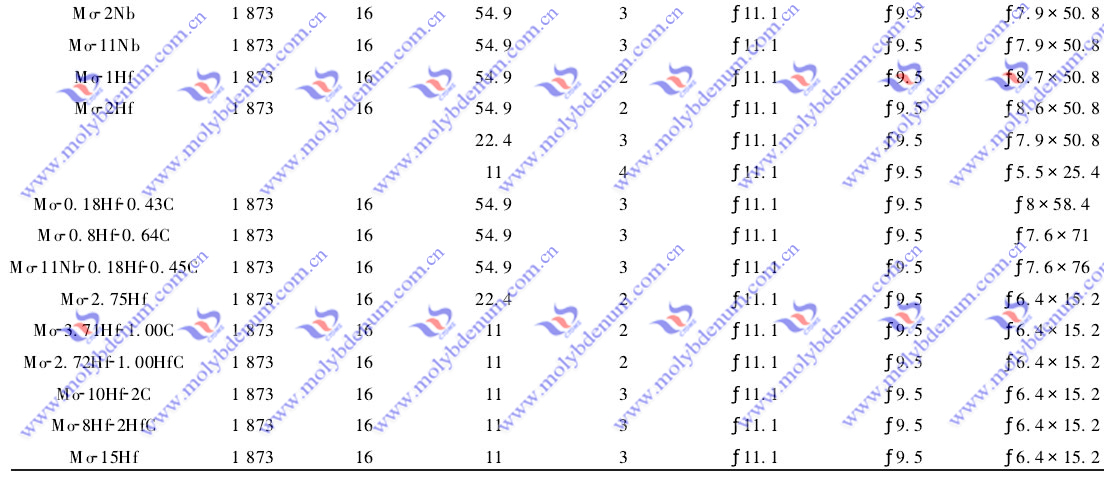

In order further to minimize gas emissions, require multiple zone melting, so as to obtain high-quality molybdenum alloy single crystal. In contrast, the liquid phase in order to minimize the loss caused by evaporation of the material, the electron beam scanning speed is too low, the number of scans is not too high. Therefore, we must determine from the system test molybdenum base alloy single crystal and the optimum process conditions, and these conditions depending on the alloy composition, each of the test procedures molybdenum alloy crystal detail in Table.

Table molybdenum base alloy single crystal production process

Nominal composition |

Sintering temperature /K |

Sintering time/

h

|

Scan speed

/mm·h-1 |

Melting times/times

|

Alloy Size /mm |

||

Before sintering |

After sintering |

After sintering |

|||||

If you have any interest in our molybdenum alloy single crystal or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.