Doping methods impact on molybdenum composite material hardness as follow:

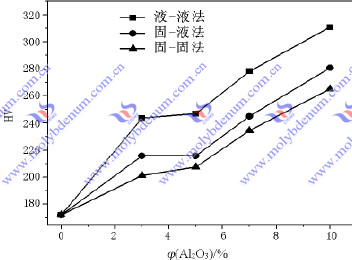

The figure below shows three kinds of doped molybdenum way prepared Al2O3/Mo composite material hardness with Al2O3 doping curve.

As can be seen from Fig.:

The hardness of the composite material of molybdenum than pure molybdenum have increased billet, which is due to the addition of Al2O3 hard phase improves the hardness of the composite material of molybdenum. Meanwhile, in the same doping level, the liquid - liquid doping on material hardness increase is most obvious, solid - liquid doped second.

Al2O3 doped with the increase, the hardness of the composite material are molybdenum remained increasing trend, though when doped Al2O3 content of 3% to 5% of the hardness changes slowly, but then increases rapidly.

This is because the addition of Al2O3 molybdenum substrate can increase the dislocation density, and the stress field is generated around it, that is caused by stress concentration, and thus play a role in strengthening the matrix. Liquid - liquid doped molybdenum composite material prepared by small particles, Al2O3 dispersed, dense tissue, and thus to improve the hardness and more obvious.

Fig. Al2O3/Mo Molybdenum Composite Material Hardness Curve

If you have any interest in our molybdenum composite material other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.