Rare Earth Molybdenum Alloy Plate Process As Follows:

Since molybdenum has a high melting point, high strength, wear resistance, thermal conductivity and a series of excellent performance characteristics, has been widely used in aerospace, petrochemical, electric light, atomic energy, metallurgy, machinery and other industrial sectors. But with modern industry and science and technology continues to evolve, and its various applications for molybdenum alloys put forward higher requirements, and the existence of molybdenum because of its own low-temperature brittleness and ductility transition temperature of these shortcomings, but also hinders it is a further application.

Domestic production of molybdenum last sheet strength is insufficient and there are defects and poor ductility, using the powder metallurgy method, add a certain amount of rare earth metals and alloy elements, and further improves the overall performance of molybdenum slab.

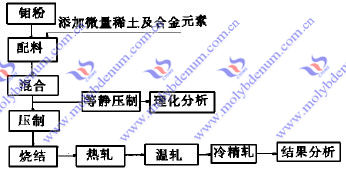

Rare molybdenum alloy slab main raw material for the production of molybdenum powder, molybdenum powder used as raw material purity: Mo ≥ 99.9%. Fsss particle size of the 2.5 ~ 3.0μm. Take a slab of industrial production of molybdenum powder, the ingredients, pressing, sintering molybdenum slab, physical and chemical testing. The indicators meet the requirements, then rolling blooming, warm rolling, cold rolling until processed into thin slices about 1.3 mm, and for punching test (in accordance with the following diagram flow).

Rare molybdenum alloy slab best process parameters are as follows:

1. Adds about 1% of La2O3 and 0.1% ~ 0.15% ZrH2 (weight ratio), can significantly improve the state of molybdenum alloy powder metallurgical tensile strength of the slab.

2. Rare earth-containing powder metallurgical state at low molybdenum alloy slab conditions with pure molybdenum TZM sheet plate and compared with excellent rolling properties and good surface quality.

If you have any interest in our rare earth molybdenum alloy plate or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.