New Enhanced Molybdenum Alloy

In the molybdenum carbide-reinforced alloy, TZM alloy(Mo-0.5Ti-0.08Zr-0.01 ~ 0.04C) Mo-0.5Ti (Mo-0.5Ti-0.01 ~ 0.O4C) has a very important role in industrial widely used. Such alloys by adding Ti, Zr, C and achieve enhanced performance and improved heat purposes.

In recent years, the international community based on the existing situation and the development of a molybdenum alloy heat several new molybdenum alloy, with the added element Hf instead of Ti, developed into the following two systems of high-temperature high-strength molybdenum alloys:

MHC Mo-Hf - C system

ZHM Mo-Hf-Zr-C system

In place of Ti, Hf reason is to use a method to enhance the formation of duplex structure molybdenum, the high-temperature behavior of molybdenum carbide relatively great influence, especially in the most effective HfC, ZrC second, TIC As low melting point, may soon gather, organize coarsening, thus strengthening effect badly. Studies have shown that, ZHM has better performance than the MHC.

In the MHC lines, Mo-1Hf-0.05C alloy is representative, is now into industrial-scale production, powder metallurgy method were spindle weight of 5 tons weight, diameter of 1300mm this alloy after forging deformation capacity 60 %, the temperature of 950-1250 ℃ TZM alloy the tensile strength ratio to be 20% higher, the direction of elongation of 10%.

Alloys and processing of this deformation, heat treatment system has a lot of different deformation between MHC plates at 1500-1600 ℃ for 1 hour in hydrogen treated with the greatest elongation at 1100-1300 ℃ between 65% of the amount of deformation of the plate strength actually increased, which may attributed to strain aging effect, which the creep resistance of the plate plays an extremely ZHM4 disc member of the MHC and rolled sheet, plate and pieces of the same pure Mo TZM tensile properties compared to reflect this situation. Pieces of sheet and plate at room temperature strength up to 1400N / m resistance, and showed ductile fracture.

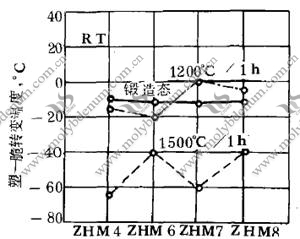

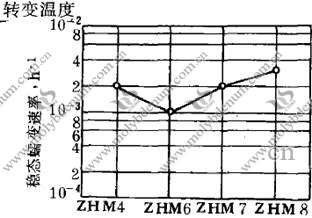

ZHM series alloy plastic one-brittle transition temperature and creep resistance as shown in Fig. 1 and Fig.2.

Fig. 1 Four kinds ZHM alloy forging plastic disc member in the radial direction - brittle transition temperature

Fig.2 Four kinds of shingling ZHM alloy stability nervous fans Rui HE level L secondary shingling, each 30% deformation, 66% of the total amount of deformation, the middle after 1200 ℃ 2 hr heat)

Integrated in this series shows the performance of each component alloy, ZHM6 has the best performance: its highest tensile strength; elongation moderate; plastic one-brittle transition temperature is low, forging state is -15 ℃, after 1200 ℃ and 1500 ℃ l hour were reduced after annealing -20 ℃ and -40 ℃; particular note is its creep rate is the lowest. Pu Lanxi metal processing claims, ZHM6 alloy coming into production.

If you have any interest in our enhanced molybdenum alloy or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.