Doping methods impact on molybdenum composite powder morphology as follow:

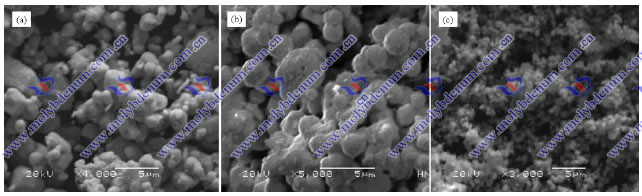

The following figure shows the same doping (φAl2O3 = 10%) under way by different doping molybdenum powder prepared Al2O3/Mo SEM photographs of the composite. From Fig. (a) shows that the solid - solid composite doped molybdenum powder prepared by the majority of its particle shape are more rules, but the larger particles and uneven size, particle size of 1 ~ 4μm.

Fig. (b) is the solid - liquid the composite doped molybdenum powder, which is relatively regular particle shape, particle size of the solid - solid doping resultant almost, but significantly improved uniformity of particle size; most particle size of 1μm so, only the individual particle size of 2μm.

Fig. (c) is liquid - liquid the composite doped molybdenum powder, the particle shape of the rule, a slight agglomeration; particle size finer than the previous two, and more uniform particle size of 05 ~ 1μm.

Fig. 10% Al2O3 Doped Molybdenum Composite Powder of the SEM photograph

The figure shows that changes in the way with doping, molybdenum powder morphology has been greatly improved, liquid - liquid doped molybdenum powder composites prepared with good morphology and particle size.

Liquid - liquid between ions doped to achieve uniform mixing, the mixture to achieve the greatest degree of homogenization, the molybdenum compound and the dopant oxide in relatively uniform pre-mixing, the final powder made of the finest granularity. It is the presence and role of doped oxide results, due to the high stability of doped oxide particles attached to the surface of molybdenum powder, molybdenum oxide can prevent gas hydrate particles deposited on the surface of molybdenum powder or the occurrence of partial solid phase chemical reaction, thereby inhibiting the molybdenum powder particles grow. Doped oxide distributed more evenly, and its effect on the refinement of molybdenum powder more obvious.

Shown in Fig. composed of three different ways of doping the composite molybdenum powder, the particle size distribution with different levels of visible way affect the doped oxide doped with molybdenum powder in the uniformity of the distribution, and then affect the final particle size of the obtained composite of molybdenum powder.

If you have any interest in our molybdenum composite powder other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.